What Are The Types of Double Jersey Circular Knitting Machine?

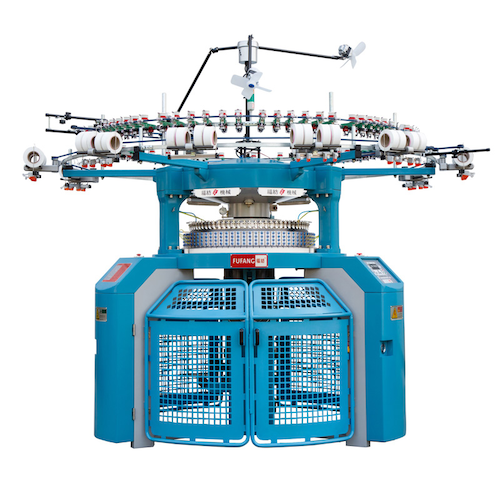

2023-04-18 22:00Double jersey circular knitting machines are used for producing a wide range of fabrics, including sports fabrics, knitwear, and stretch fabrics. These machines use two needle beds to knit two layers of fabric simultaneously, producing a double-layered fabric that is both durable and comfortable.

There are several types of double jersey circular knitting machines available on the market, each with its unique features and capabilities. In this article, we will explore some of the most popular types of double jersey circular knitting machines.

1、Rib Knitting Machine: This machine is designed for producing fabrics that have ribs or vertical wales on one side and plain stitches on the other side. It is commonly used for making cuffs, collars, and waistbands for clothing.

2、Interlock Knitting Machine: Interlock machines produce a fabric that looks the same on both sides, making it suitable for reversible garments. This machine is capable of knitting a wide range of patterns and designs, including stripes, checks, and jacquard patterns.

3、Purl Knitting Machine: Purl machines are used for producing fabrics with a raised or textured surface. This machine is ideal for creating fabrics with a high degree of elasticity, making it suitable for sportswear and other stretch fabrics.

4、Full Electronic Knitting Machine: Full electronic machines use computerized controls to produce complex patterns and designs with high precision. These machines are often used for producing high-end fashion fabrics, such as lace, embroidery, and other intricate designs.

5、Jacquard Knitting Machine: Jacquard machines are used for producing fabrics with intricate designs and patterns, including logos, graphics, and images. These machines use a series of punched cards or computerized controls to produce the desired pattern.

Double jersey circular knitting machines are an essential tool for the textile industry, and there are several types of machines available to suit different fabric requirements. By understanding the unique features and capabilities of each machine type, manufacturers can select the most appropriate machine for their specific needs and produce high-quality fabrics efficiently.