Do you understand the structure and classification of knitting machines?

2022-12-05 22:00Do you understand the structure and classification of knitting machines?

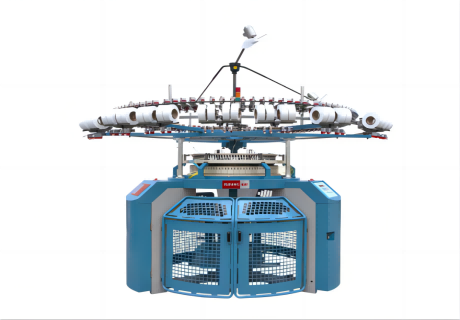

1. The general structure of knitting machines There are many types of knitting machines, but no matter what type of knitting machine, their main structure is basically the same, but the knitting is different according to the working requirements of various machines, and the specific mechanism composition is different, and Equipped with auxiliary mechanisms for different purposes. The mechanism of the machine can be roughly divided into two parts, namely the main mechanism and the auxiliary mechanism.

(1) The main mechanism of the knitting machine

1. Loop forming mechanism

The knitting mechanism is a mechanism that bends the yarn to form a coil, and makes the coils overlap each other to form a knitted fabric. Its main parts include knitting needles, sinkers, cam devices and yarn guide devices, etc. These parts are collectively called knitting parts. They are driven or fixed by the main shaft through their respective transmission mechanisms, and cooperate with each other to form a loop.

2. Yarn feeding mechanism

The yarn feeding mechanism is a mechanism that sends the yarn on the bobbin or warp beam to the knitting mechanism at a certain tension and speed according to the requirements of the weaving system.

3. Design mechanism

The design and color mechanism is called the needle selection mechanism in weft knitting, and its function is to select the knitting needles or sinkers and other parts according to the requirements of the pattern. The design and color mechanism is called the bar traverse mechanism in warp knitting. Its function is to control the bar that is fixed with the guide needle, and make it move along the direction of the needle bed and the needle back horizontally in the direction of the needle bed according to the law required by the pattern.

4. Transmission mechanism

It is a mechanism that uses the main shaft as the main body to move various parts of the machine through various transmission parts such as cams, eccentric connecting rods, worm gears and gears.

5. Control mechanism

It is an institution that enables various institutions to coordinate with each other in accordance with weaving requirements.

6. Pulling and winding mechanism

It is a mechanism that draws the fabric out of the weaving area and rolls it into a roll with a certain tension and speed.

(2) Auxiliary mechanism of knitting machine

1. Reducer

In order to adjust the machine, the knitting machine is equipped with a deceleration device to make the machine run at a slow speed, which is convenient for maintenance and adjustment.

2. Self-stop device

It includes automatic stop devices such as machine failure, safety, yarn breakage, fabric surface defects, over- or under-tension, limited package capacity, etc.

3. Various instruments

Depending on the model, the knitting machine is equipped with a machine speedometer, a let-off speedometer and a counter, etc.

4. Expand the variety of designs and varieties

It includes jacquard mechanism, yarn pressing rod, pattern pressing plate, intermittent warp let-off and multi-speed warp let-off and other mechanisms.