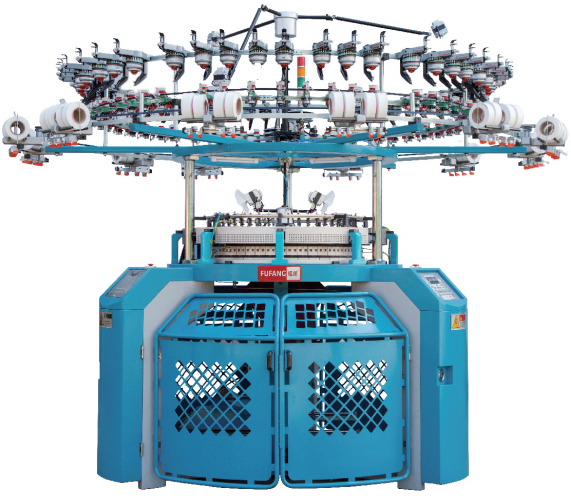

Maintenance of knitting mechanism of circular knitting machine

2024-04-19 20:00Maintenance of knitting mechanism of circular knitting machine

The knitting mechanism is the heart of the circular knitting machine. It directly affects the quality of the product, so the maintenance of the knitting mechanism is very important.

A. After the circular knitting machine has been running normally for a period of time (the length of time depends on the quality of the equipment and the knitting materials), the needle slot needs to be cleaned to prevent dirt from being woven into the fabric along with the knitting needles, and at the same time, it can also reduce needle defects (also The emergence of needle paths).

B. Check whether all knitting needles and sinkers are damaged. If damaged, they must be replaced immediately. If the use time is too long and the quality of the fabric is affected, you need to consider replacing all knitting needles and sinkers.

C. Check whether the needle groove walls of the needle disk and needle barrel are damaged. If any problems are found, repair or replace them immediately.

D. Check the wear of the triangle and confirm whether it is installed correctly and whether the screws are tightened.

E. Check and correct the installation position of the yarn feeder. If serious wear is found, it needs to be replaced immediately.

Lubrication of circular knitting machines

A. Check the oil level mirror of the large plate every day. If the oil level is lower than 2/3 of the mark, you need to add oil. During the half-year maintenance, if any sediment is found in the oil, all the oil should be replaced with new oil.

B. If the transmission gear is oil-stained, oil should be added every 180 days (6 months); if it is grease lubricated, grease should be added every 15 to 30 days.

C. During the half-year maintenance, check the lubrication condition of the transmission bearings everywhere and add grease.

D. All knitted parts must use lead-free knitting oil, and day shift personnel are responsible for refueling.