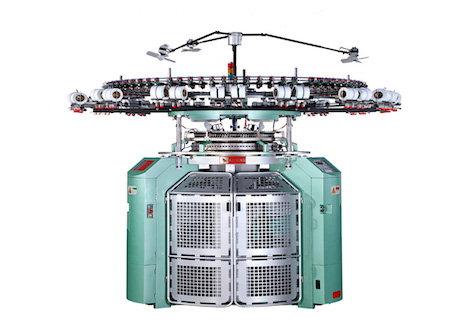

Daily maintenance of large circular knitting machine

2023-02-03 22:00Daily maintenance of large circular knitting machine

The high speed and high precision of modern weaving machinery put forward higher requirements for maintenance and maintenance. For this reason, the daily maintenance and maintenance of large circular knitting machines must be implemented in daily production. If the machine is well maintained, it can play a greater role in the machine. Potential to win greater economic benefits.

1 day maintenance

(1) Remove the lint and fluff attached to the creel and the surface of the machine every shift. Keep the weaving parts and take-up device clean.

(2) Check the self-stop device and safety device every shift, and repair or replace it immediately if there is any abnormality.

(3) Check the active yarn feeding device every shift, if there is any abnormality, remove it for repair or replace it immediately.

(4) Check the oil level mirror of the big crank plate and the oil level pipe of the fuel injection machine every shift.

2 week maintenance

(1) Clean the yarn-feeding speed-regulating aluminum disc, and remove the lint accumulated in the disc. Check whether the tension of the conveyor belt is normal.

(2) Check whether the belt tension of the transmission system is normal and whether the transmission is stable.

(3) Check the operation of the cloth winding machine.

3 months warranty

(1) Remove the upper and lower plate triangular seats, and remove the accumulated lint.

(2) Clean the dust removal fan and check whether the blowing direction is correct.

(3) Clean the lint in all electrical accessories.

(4) Review the performance of all electrical accessories (including self-stop system, safety alarm system, detection system).

4 Semi-annual maintenance

(1) Clean the machine table. Thoroughly clean the upper and lower dials, including knitting needles and sinkers, select all knitting needles and sinkers, and replace them immediately if they are damaged.

(2) Clean the fuel injector and check whether the oil passage is unblocked.

(3) Clean and check the positive yarn storage device.

(4) Clean the cotton wool and oil stains in the motor and transmission system.

(5) Check whether the waste oil collection circuit is unblocked.